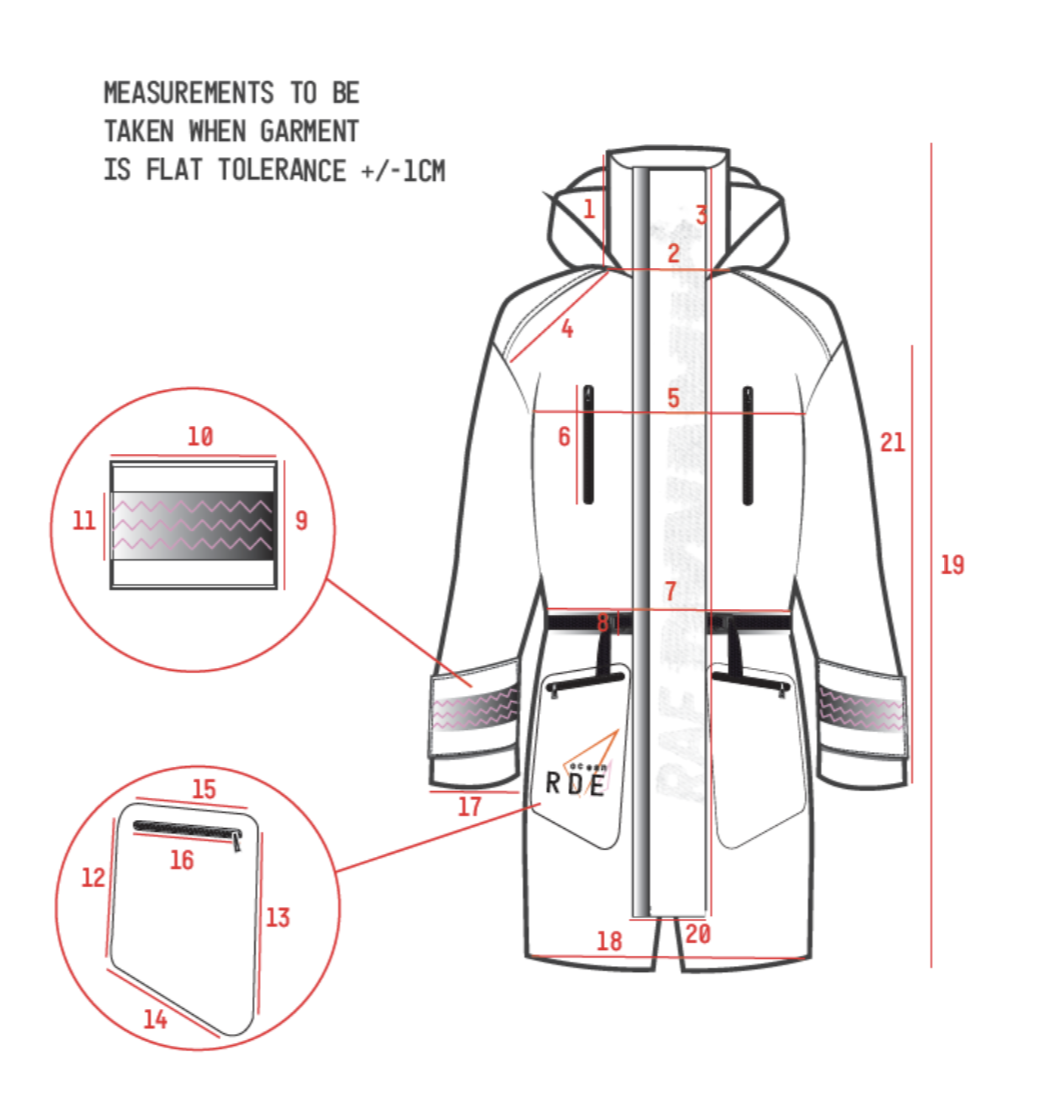

This week has been very productive and I’ve really enjoyed becoming even more familiar with using Clo3D – but trying to reach the end goal of the project (virtually simulating the Sailing Jacket in graded S / M / L sizes) has proven more difficult than I originally anticipated.

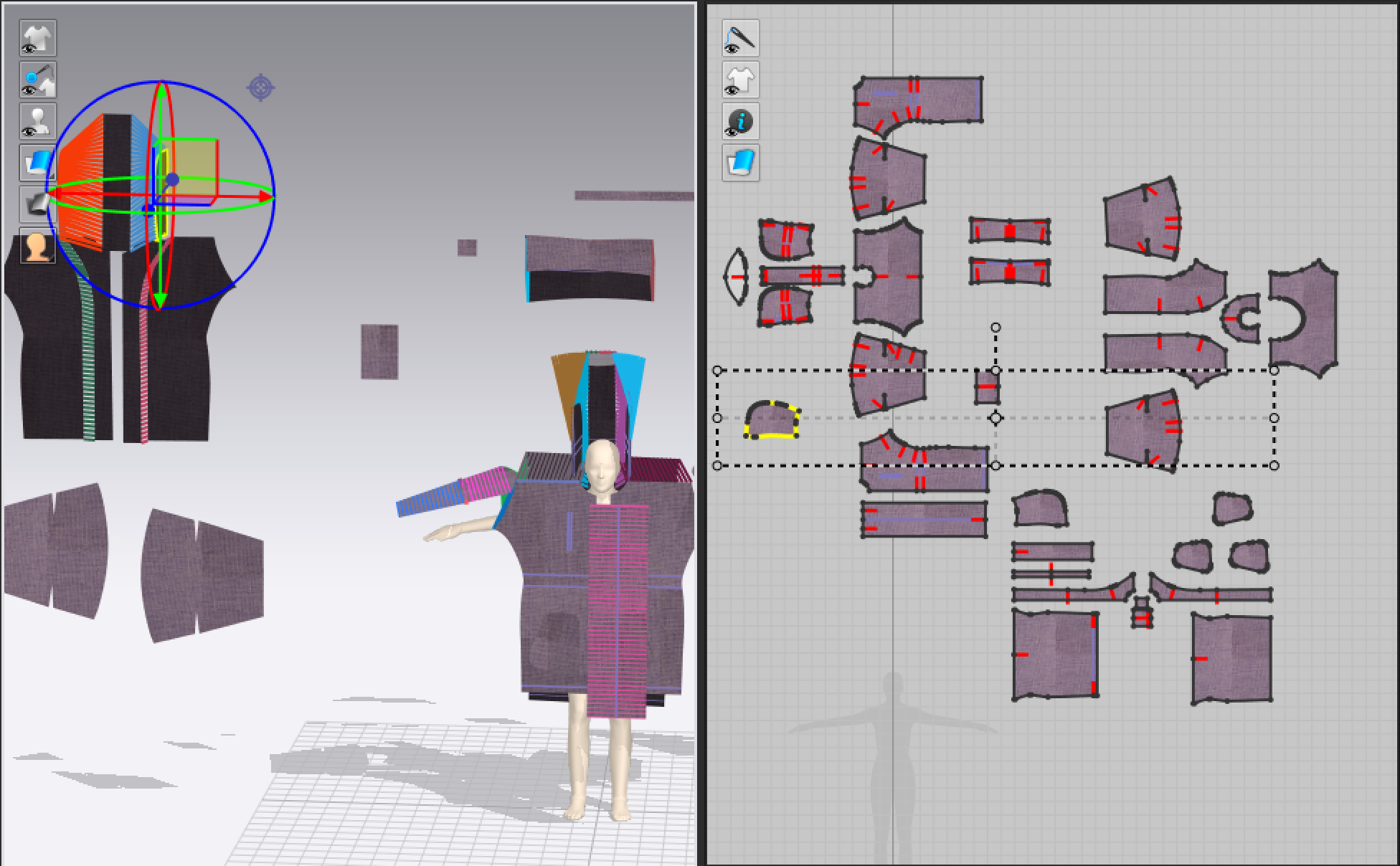

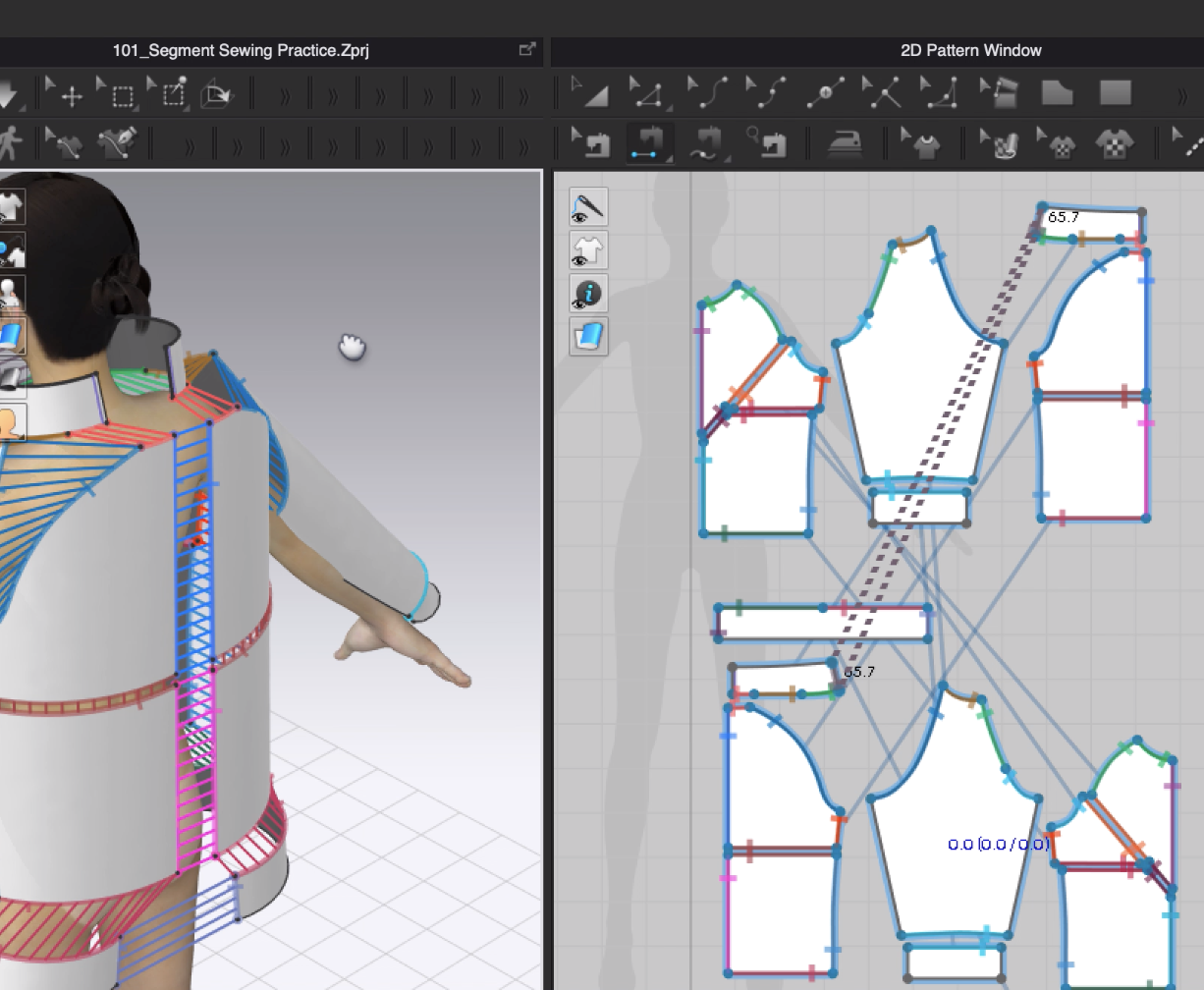

The Gerber patterns have now been cleaned up; removing seam allowances and opening darts ready for transferring across to Clo3D. I have put my new skills in Clo3D to the test by arranging and sewing the sailing jacket together as well as I can. Doing this for a lined garment has proven challenging as I’ve only been using the software for 3 weeks now. But I do feel like I am becoming more confident in using it the more I practice and the more I am forced to problem solve whilst sewing the garment together. The main difficulty at the moment is trying to simulate the correct fabric in Clo3D in order to let the garment fall properly over the avatar.

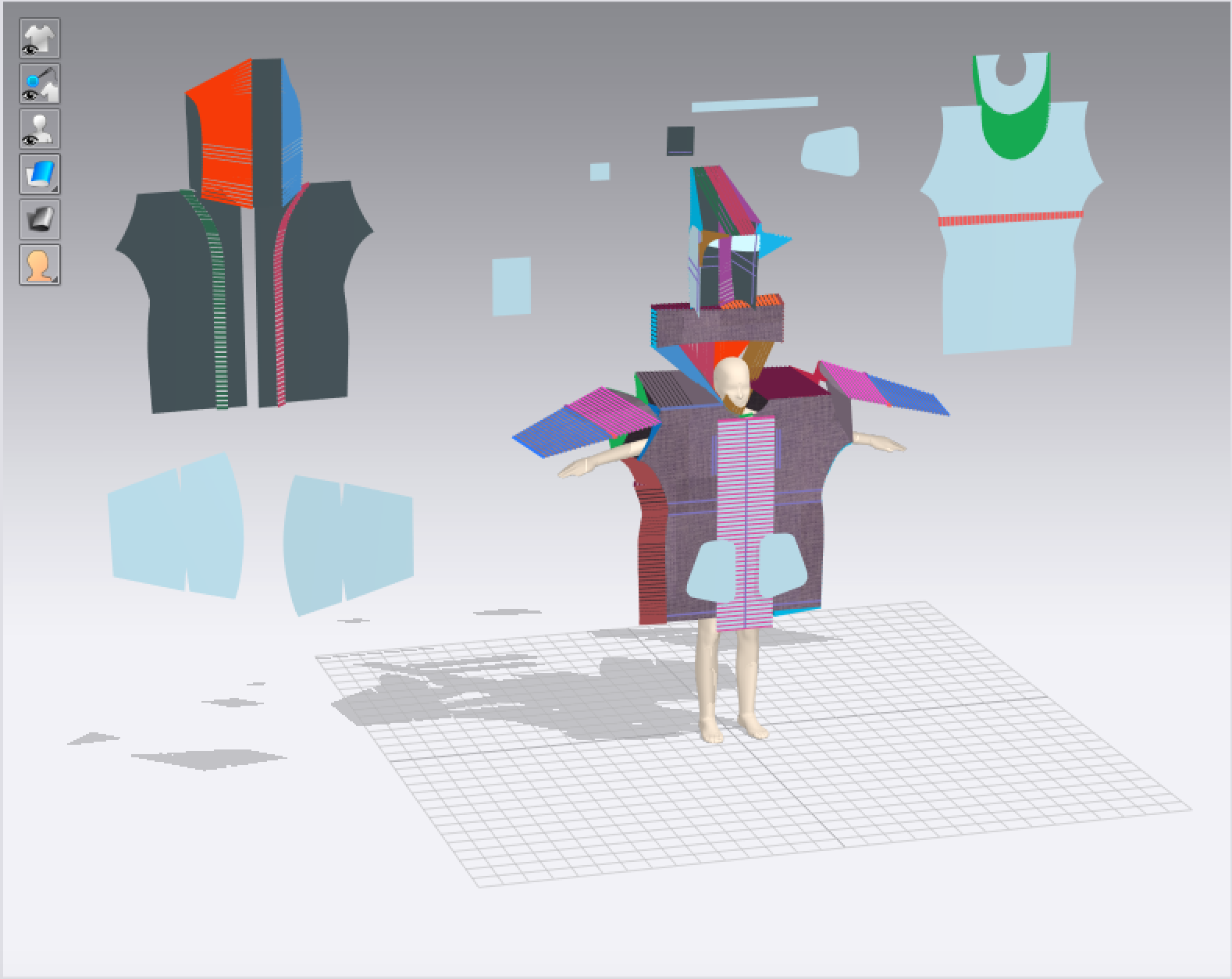

3D window

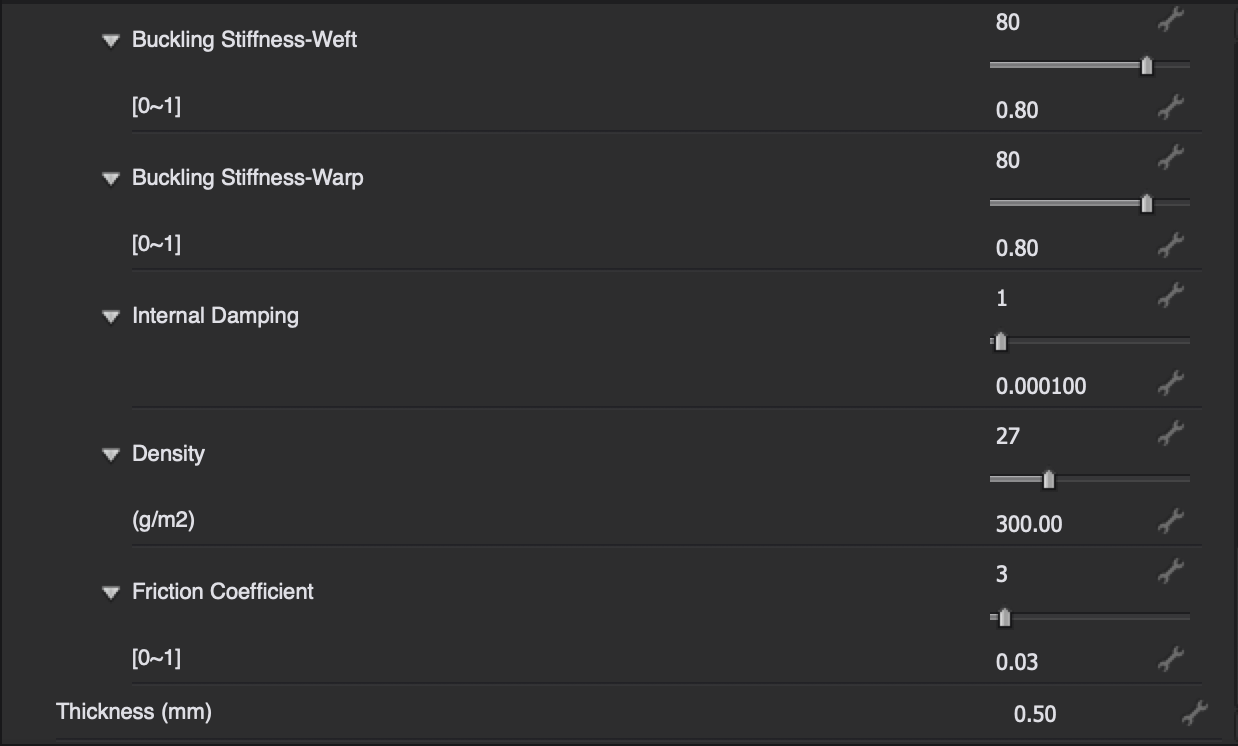

On Wednesday I spent the morning in the textile testing lab (in Manchester Fashion Institute) and was introduced to FAST, a method of textile testing developed in Australia for quick testing of textile materials. Although originally developed for testing lightweight suiting fabrics, it can be used across a range of fabrics. I trialed the method using a standard polycotton suiting fabric, then input these test results into Clo3D to simulate the fabric as best as I could. I found that the testing itself was very straight forward to do, as I am familiar with lab-based textile testing and can easily follow algebraic formulae to work out the results in line with the given units.

However, despite obtaining accurate results from the testing, it proved almost impossible to form a correlation between these numeric results and the specifications of Clo3D. Because Clo is such a design-based software, there are few units provided when inputting the fabric properties (there are many sliders that can alter the value of each property – but these are not clearly correlated to numeric values). I have tried to simulate the test fabric to the best of my ability and am currently trialling the sailing jacket in this fabric, but I’m unsure as to how I will successfully simulate the final fabrics.